南京大学学报(自然科学版) ›› 2024, Vol. 60 ›› Issue (2): 345–355.doi: 10.13232/j.cnki.jnju.2024.02.015

• • 上一篇

基体配比对VIHPS制备GO⁃CF/EP复合材料微观组织与形状记忆性能的影响

马玉钦1( ), 吕晋书1, 阮鸥2, 徐津3, 任斌1, 王刚锋1, 庞利沙1

), 吕晋书1, 阮鸥2, 徐津3, 任斌1, 王刚锋1, 庞利沙1

- 1.道路施工技术与装备教育部重点实验室, 长安大学工程机械学院,西安,710064

2.威睿电动汽车技术(宁波)有限公司,宁波,315336

3.极氪汽车(宁波杭州湾新区)有限公司,宁波,315300

Effect of matrix ratio on microstructure and shape memory properties of GO⁃CF/EP composites prepared by VIHPS

Yuqin Ma1( ), Lü Jinshu1, Ou Ruan2, Jin Xu3, Bin Ren1, Gangfeng Wang1, Lisha Pang1

), Lü Jinshu1, Ou Ruan2, Jin Xu3, Bin Ren1, Gangfeng Wang1, Lisha Pang1

- 1.key Laboratory of Road Construction Technology and Equipment of MOE, College of Engineering Machinery, Chang'an University, Xi'an, 710064, China

2.Weirui Electric Vehicle Technology (Ningbo) Co. Ltd. , Ningbo, 315336, China

3.Jike Automobile (Ningbo Hangzhou Bay New Area) Co. Ltd. , Ningbo, 31530, China

摘要:

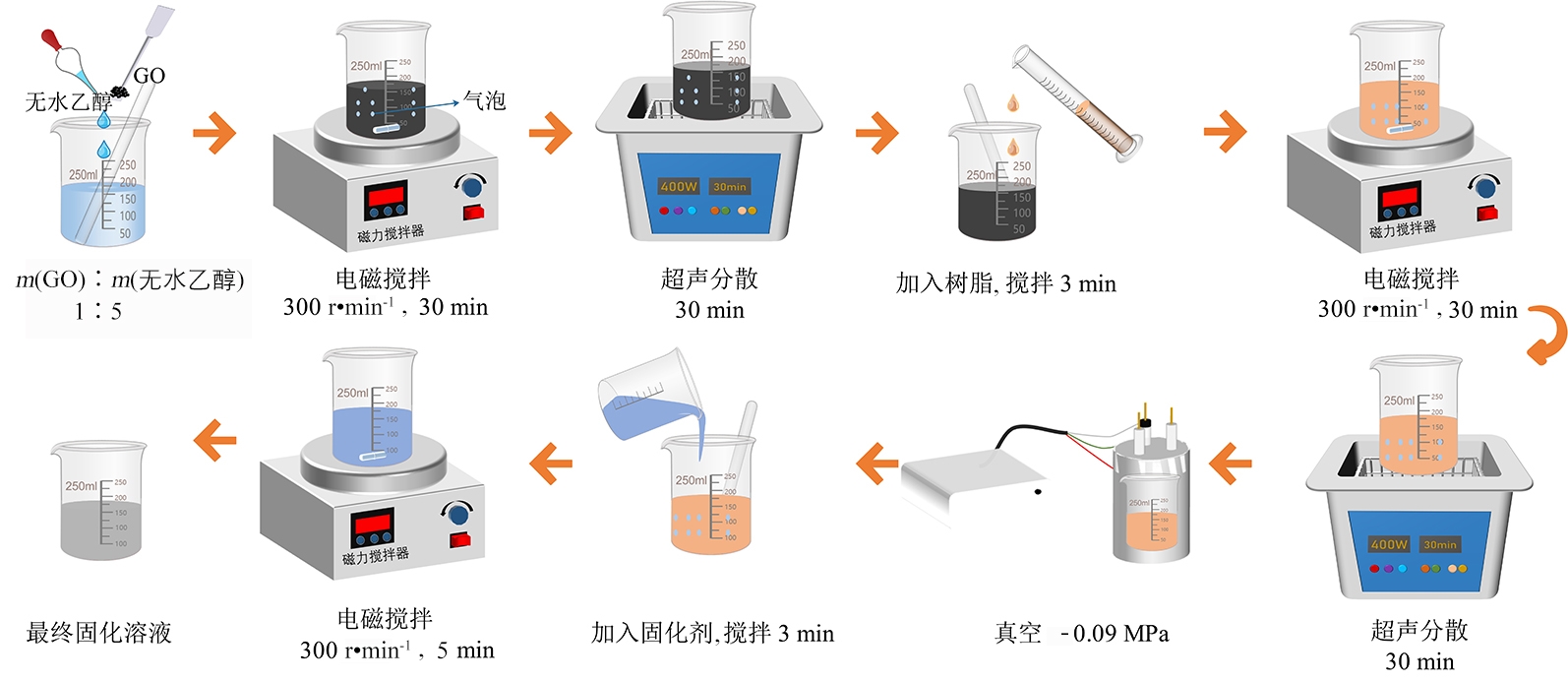

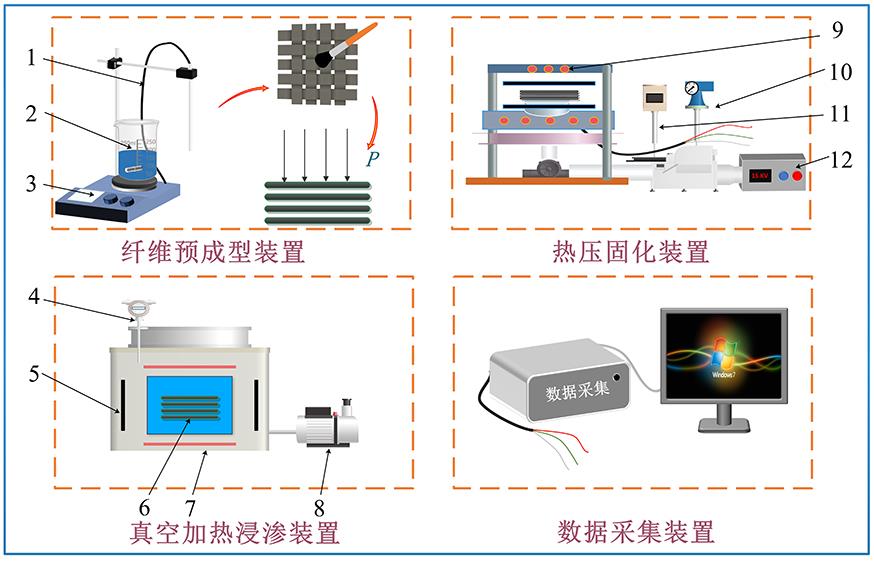

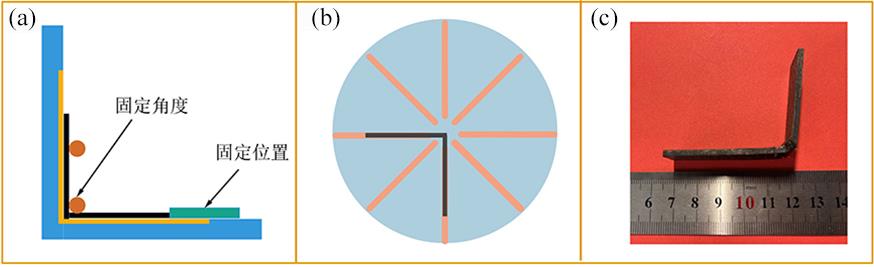

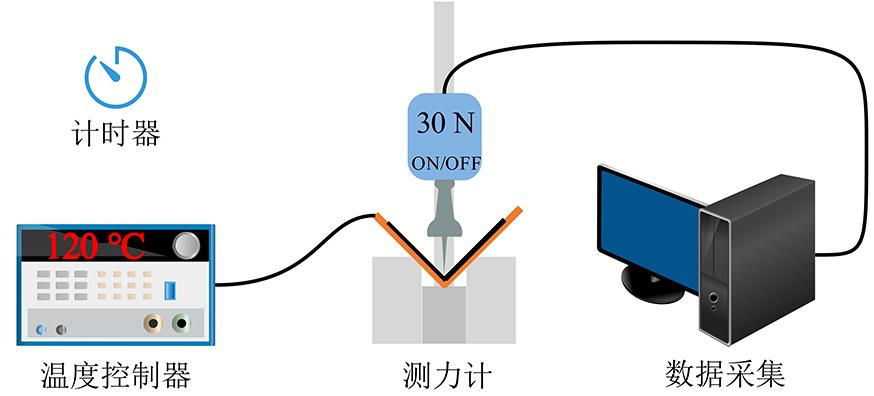

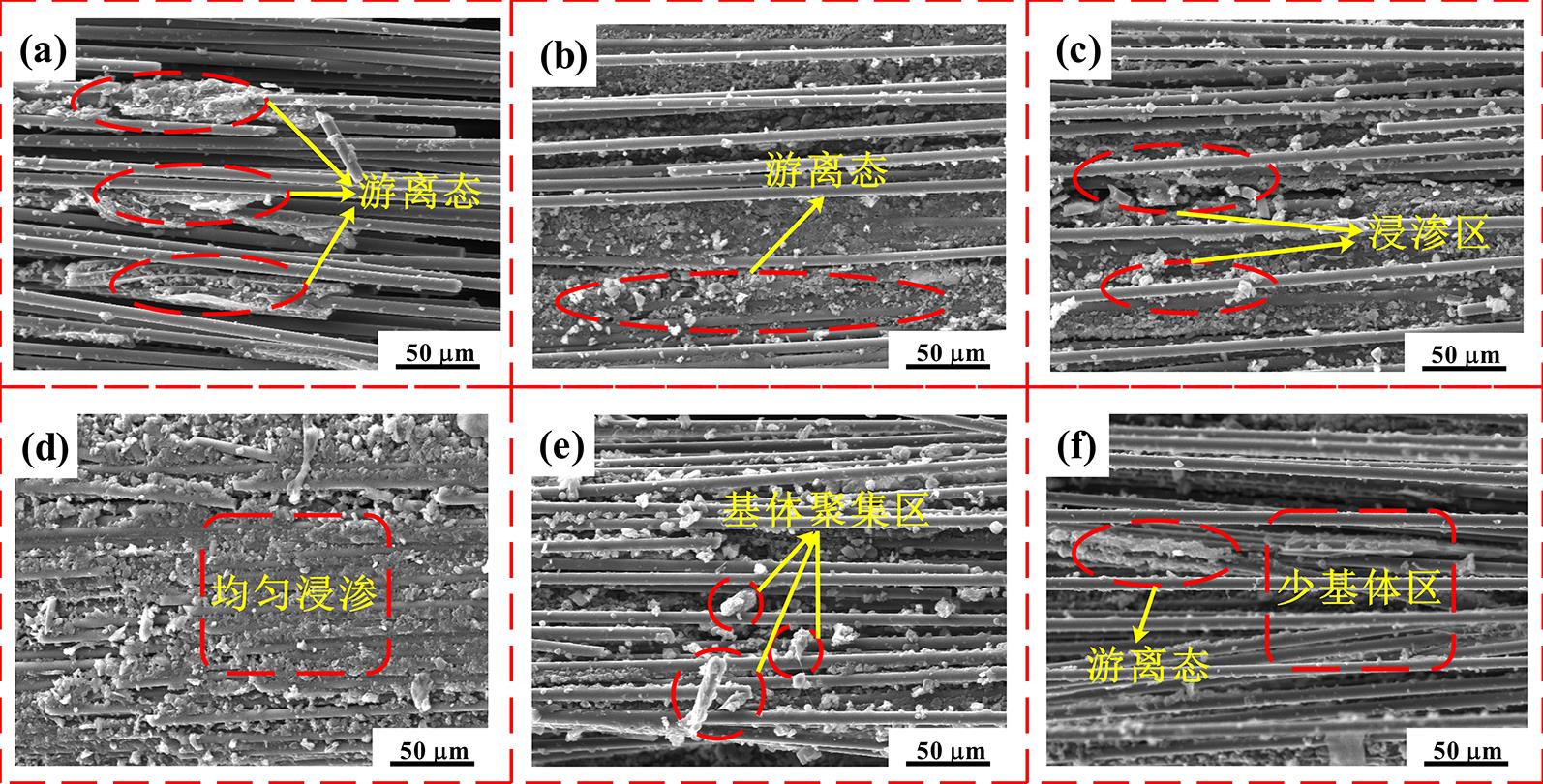

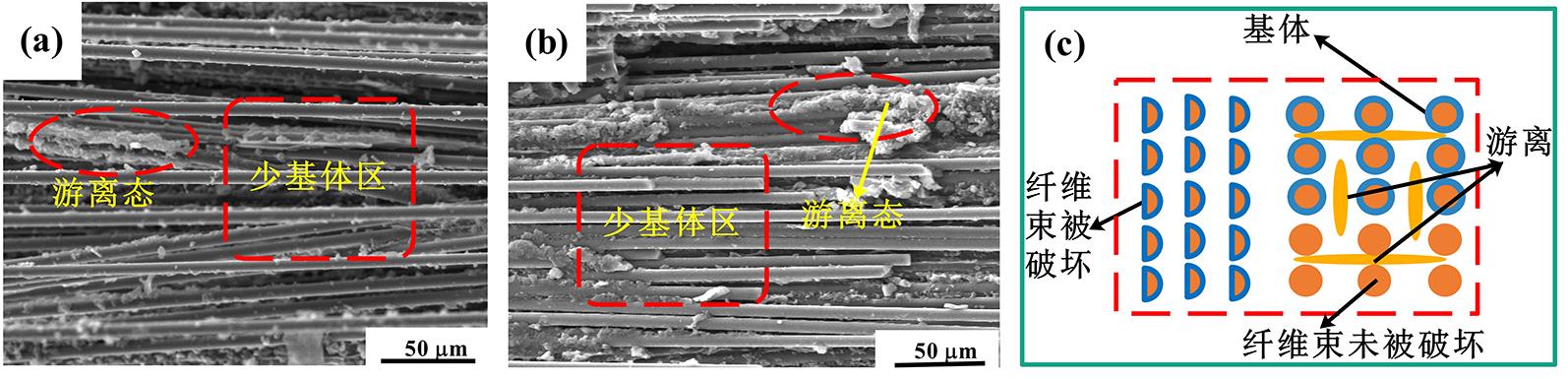

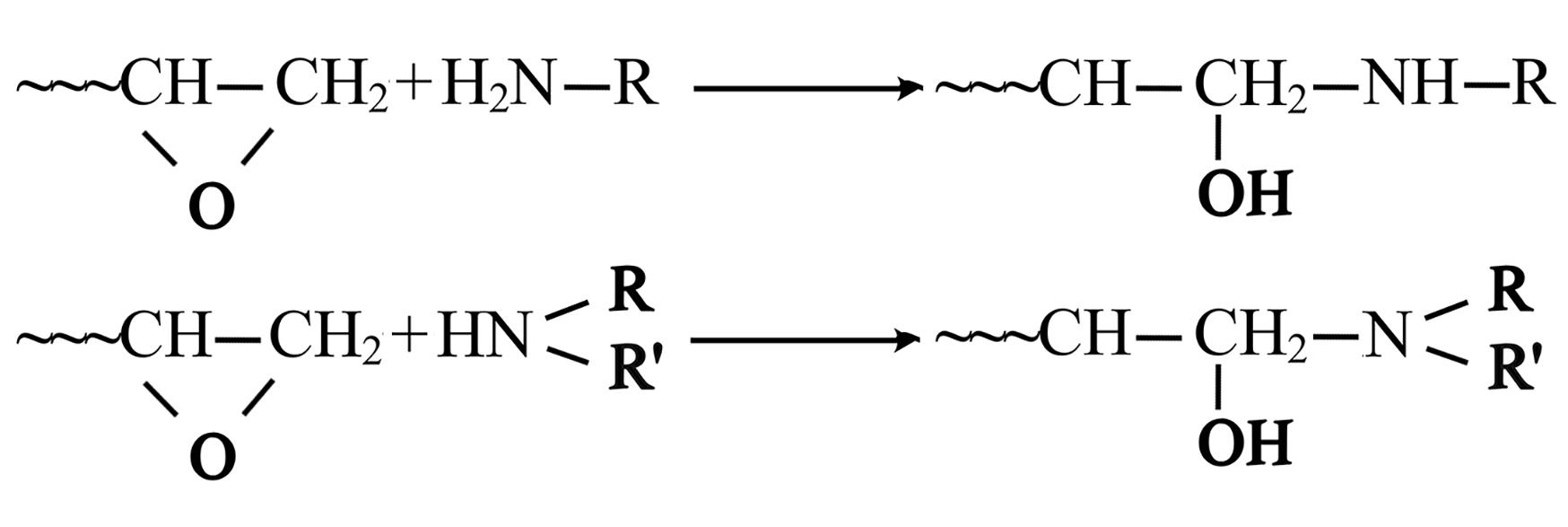

碳纤维混杂增强复合材料由于具有重量轻、可设计性强等诸多优点,广泛用于汽车、海洋、航空航天等行业.根据固化剂与环氧树脂的配比化学原理,计算出石墨烯?碳纤维混杂增强树脂基(GO?CF/EP)复合材料的最佳配比为1∶5,并采用真空浸渗热压成型工艺(VIHPS)制备1∶2~1∶7共六个配比的试样,结合形状记忆性能测试及微观形貌的观察,得到固化剂与环氧树脂实际最佳配比.实验结果表明,GO?CF/EP复合材料性能主要取决于体系中交联度的大小,交联度越大,复合材料的形状记忆性能越好,微观组织形貌也较理想.当基体配比为1∶5时,GO?CF/EP复合材料体系中交联度最大,微观形貌呈现均匀致密的状态,形状固定率最大,为95.90%;形状回复率最大,为95.40%;形状回复时间最短,为80.30 s;形状回复力最大,为9.48 N.当基体配比为1∶2或1∶7时,固化剂过量或不足,交联度较小,微观组织形貌中有大量的基体聚集区,其形状记忆性能下降,形状固定率及回复率也相应减小,分别为82.99%,81.66%,81.91%,78.75%;形状回复力分别只有5.20 N和5.50 N.

中图分类号:

- O635.1

| 1 | 游晋. 形状记忆材料的力学性能研究与盘绕式空间伸展臂的研制. 硕士学位论文. 上海:上海交通大学,2017. |

| You J. Development of a callable space mast and study on mechanical properties of shape memory materials. Master Dissertation. Shanghai:Shanghai Jiao Tong University,2017. | |

| 2 | Gao H, Li J R, Xu F G,et al. Interpenetrating shape memory polyimide?polyaniline composites with electrical conductivity. Polymer Composites,2023,44(7):4134-4141. |

| 3 | 袁文华. 基于特殊晶相构筑形状记忆聚合物材料. 博士学位论文. 杭州:浙江大学,2022. |

| Yuan W H. Preparation of shape memory polymer materials based on unconventional crystalline phases. Ph.D. Dissertation. Hangzhou:Zhejiang University,2022. | |

| 4 | Ozair H, Rehman M A U, Baluch A H,et al. Impact energy absorption analysis of shape memory hybrid composites. Journal of Composites Science,2022,6(12):365. |

| 5 | Mu T, Liu L W, Lan X,et al. Shape memory polymers for composites. Composites Science and Technology,2018,160:169-198. |

| 6 | 杨增辉,张耀明,张新瑞,等. 高温形状记忆聚合物研究进展. 功能高分子学报,2022,35(4):314-327. |

| Yang Z H, Zhang Y M, Zhang X R,et al. Research progress of high temperature shape memory polymers. Journal of Functional Polymers,2022,35(4):314-327. | |

| 7 | Liang X, Li X J, Tang Y,et al. Hyperbranched epoxy resin?grafted graphene oxide for efficient and all?purpose epoxy resin modification. Journal of Colloid and Interface Science,2022,611:105-117. |

| 8 | 王爽. 自增强环氧树脂复合材料的制备与性能研究. 博士学位论文. 北京:北京化工大学,2018. |

| Wang S. Preparation and performance of epoxy resin particle modified epoxy resin composite materials. Ph.D. Dissertation. Beijing:Beijing University of Chemical Technology,2018. | |

| 9 | 王恩亮. 石墨烯/环氧树脂形状记忆复合材料制备与性能研究. 硕士学位论文. 杭州:浙江理工大学,2019. |

| Wang E L. Fabrications and properties of graphene/epoxy memory composites. Master Dissertation. Hangzhou:Zhejiang Sci?Tech University,2019. | |

| 10 | Zhang L X, Jiao H Q, Jiu H F,et al. Thermal,mechanical and electrical properties of polyurethane/(3?aminopropyl) triethoxysilane functionalized graphene/epoxy resin interpenetrating shape memory polymer composites. Composites Part A:Applied Science and Manufacturing,2016,90:286-295. |

| 11 | 周露. 耐高温形状记忆环氧树脂基复合材料性能研究. 硕士学位论文. 沈阳:沈阳航空航天大学,2018. |

| Zhou L. Study on properties of high temperature resistant shape memory epoxy resin matrix com?posites. Master Dissertation. Shenyang:Shenyang Aerospace University,2018. | |

| 12 | 易凯,耿东兵,杨智勇,等. 树脂含量对F?8H3/602芳纶复合材料性能的影响. 宇航材料工艺,2015,45(2):59-63. |

| Yi K, Geng D B, Yang Z Y,et al. Effect of resin content on performances of aramid fiber reinforced composites. Aerospace Materials & Technology,2015,45(2):59-63. | |

| 13 | 张代军,陈俊,包建文,等. 树脂基体中热塑性树脂含量对碳纤维环氧复合材料Ⅱ型层间断裂韧性的影响. 材料工程,2021,49(6):178-184. |

| Zhang D J, Chen J, Bao J W,et al. Effects of thermoplastic resin content on mode?Ⅱ interlaminar fracture toughness of carbon fiber reinforced epoxy composite. Journal of Materials Engineering,2021,49(6):178-184. | |

| 14 | 柴红梅,汪鹏,王雷,等. 固化剂含量对RTM用环氧树脂体系固化性能的影响. 玻璃钢/复合材料,2009(6):48-49,76. |

| Chai H M, Wang P, Wang L,et al. Effect of curing agent content on RTM epoxy system curing properties. Fiber Reinforced Plastics/Compo?sites,2009(6):48-49,76. | |

| 15 | 张集滕,李瑞. 树脂和固化剂含量对自硬呋喃树脂砂抗拉强度的影响. 铸造,2012,61(11):1361-1362. |

| Zhang J T, Li R. Effects of furan resin and hardener contents on tensile strength of no?bake furan resin sand. Foundry,2012,61(11):1361-1362. | |

| 16 | 夏凯欣. 真空浸渗制备AZ 91D/SiCP复合材料的性能研究. 硕士学位论文. 长春:吉林大学,2019. (Xia K X. Study on the properties of AZ 91 |

| D/SiCP composites prepared by vacuum infiltration. Master Dissertation. Changchun:Jilin University,2019. | |

| 17 | Wang A Y, Liu C, Hu L X,et al. Effects of processing on mechanical properties of B4C?graphene composites fabricated by hot pressing. Materials Science and Engineering:A,2021,808:140872. |

| 18 | 王杰. 真空浸渗热压形状记忆复合材料及其性能研究. 硕士学位论文. 西安:西安电子科技大学,2021. |

| Wang J. Research on vacuum infiltration and hot?pressed shape memory composite material and its performance. Master Dissertation. Xi'an:Xidian University,2021. | |

| 19 | Ma Y Q, Wang J, Zhao Y T,et al. A new vacuum pressure infiltration CFRP method and preparation experimental study of composite. Polymers,2020,12(2):419. |

| 20 | Zhi L, Zhang C Q, Liu Z Z,et al. Flexible decorative wood veneer with high strength,wearability and moisture penetrability enabled by infiltrating castor oil?based waterborne polyurethanes. Composites Part B:Engineering,2022,230:1095202. DOI:10.1016/j.compositesb.2021.109502 . |

| 21 | Bajuri F, Mazlan N, Ishak M R. Water absorption analysis on impregnated kenaf with nanosilica for epoxy/kenaf composite. IOP Conference Series:Materials Science and Engineering,2018,405:012013. DOI:10.1088/1757-899x/405/1/012013 . |

| 22 | 龚燕妮. 真空压力浸渗SiC/Al复合材料工艺过程数值模拟研究. 硕士学位论文. 北京:北京理工大学,2015. |

| Gong Y N. Study on numerical simulation of gas pressure infiltration SIC/Al ceramic matrix composites. Master Dissertation. Beijing:Beijing Institute of Technology,2015. | |

| 23 | 耿兆军. 环氧基碳纤维复合材料的形状记忆性能及其机理研究. 硕士学位论文. 北京:北京化工大学,2021. |

| Geng Z J. Study on shape memory performances and mechanisms of epoxy?based carbon fiber composites. Master Dissertation. Beijing:Beijing University of Chemical Technology,2021. | |

| 24 | Ma Y Q, Wang J, Li S S,et al. Effect of molding temperature on shape memory performance of SMPC. Integrated Ferroelectrics,2020,209(1):30-39. |

| 25 | Guo H Y, Ma Y Q, Wang G F,et al. Effect of cyclic tests on the shape memory performance of GO?CF hybrid?reinforced SMPC. Polymer Composites,2022,43(8):5076-5086. |

| 26 | 孙鹤. 具有二阶段固化特征形状记忆环氧固化动力学及性能研究. 硕士学位论文. 哈尔滨:哈尔滨工业大学,2018. |

| Sun H. Study on curing kinetics and properties of epoxy with shape memory charac?teristics of two?stage curing. Master Dissertation. Harbin:Harbin Institute of Technology,2018. | |

| 27 | 刘雅芸. 形状记忆环氧树脂及其复合材料的性能与应用研究. 博士研究论文. 北京:中国地质大学(北京),2019. |

| Liu Y Y. Study on properties and application of shape memory epoxy (SMEP) and its composites. Ph.D. Dissertation. Beijing:China University of Geosciences (Beijing),2019. | |

| 28 | Zhou J L, Zhang C Y, Cheng C,et al. Synergetic improvement of interlaminar fracture toughness in carbon fiber/epoxy composites interleaved with PES/PEK?C hybrid nanofiber veils. Advanced Fiber Materials,2022,4(5):1081-1093. |

| 29 | Liu S Y, Yu M J, Feng Y J,et al. Simultaneous improvement of interfacial bonding and thermal resistance of carbonaceous fiber/silicone composite coatings modified with aniline?methyl?triethoxysilane. Progress in Organic Coatings,2023,183:107735. DOI:10.1016/j.porgcoat.2023.107735 . |

| 30 | Hu L, Cai Y, Yang W F,et al. Laser selective ablated multistep interfacing for enhanced adhesive bonding joints of carbon fiber reinforced polymer materials. Journal of Laser Applications,2021,33(4):042005. DOI:10.2351/7.0000378 . |

| 31 | Wang D L, Zhang F L, Huang K,et al. Study on preparation and performance of advanced nano?modified epoxy asphalt. Journal of Applied Polymer Science,2023,140(14):e53688. DOI:10.1002/app.53688 . |

| 32 | 张代军,陈俊,包建文,等. 树脂基体中热塑性树脂含量对碳纤维环氧复合材料压缩性能的影响. 复合材料科学与工程,2021(5):31-36. |

| Zhang D J, Chen J, Bao J W,et al. Effects of thermoplastic resin content on longitudinal compressive performance of carbon fiber reinforced epoxy composites. Composites Science and Engineering,2021(5):31-36. | |

| 33 | Holmstr?m M, Wilhelmsson B. Respiratory symptoms and pathophysiological effects of occupational exposure to formaldehyde and wood dust. Scandinavian Journal of Work,Environment & Health,1988,14(5):306-311. |

| 34 | 王建,吕建,徐晓伟,等. 固化剂含量对玻纤增强酚醛复合材料性能的影响. 塑料科技,2009,37(7):82-85. |

| Wang J, Lv J, Xu X W,et al. Effect of curing agent content 011 properties of glass fiber reinforced phenolic resin composite. Plastics Science and Technology,2009,37(7):82-85. | |

| 35 | 隋微微. 环氧树脂基形状记忆复合材料的研究. 硕士学位论文. 哈尔滨:哈尔滨工业大学,2008. |

| Sui W W. Study on composites of shape memory epoxy resin. Master Dissertation. Harbin:Harbin Institute of Technology,2008. |

| No related articles found! |

|

||